Statkraft Nore 1: Unique and robust repair method

The Nore 1 hydropower plant recently underwent a challenging repair when a crack appeared in the turbine house’s crossbeam. With a special repair method called metal stitching, Stryvo took on the challenge of preserving the historic infrastructure without having to replace expensive and complex parts.

Metal stitching can replace welding where it is not possible and can therefore save plants substantial costs. The method is particularly well-suited for older facilities with materials that require careful handling. Statkraft sees great advantages in combining experience and precision to extend the life of the power plant.

Background

Nore 1 is a large power plant, and reactions in the concrete expose mechanical parts to stress. As a result, components sometimes crack. Many of these components are complex or embedded, making them very difficult and expensive to replace. Some parts of the facility also use materials that cannot be welded.

«We have used Stryvo on several occasions. Performing repairs on a power plant with parts that are nearly a hundred years old requires knowledge and precision. We find it extremely cost-effective to perform maintenance and repairs instead of replacing parts.»

Ole Gunnar Haug, Maintenance Manager at Statkraft

The Solution

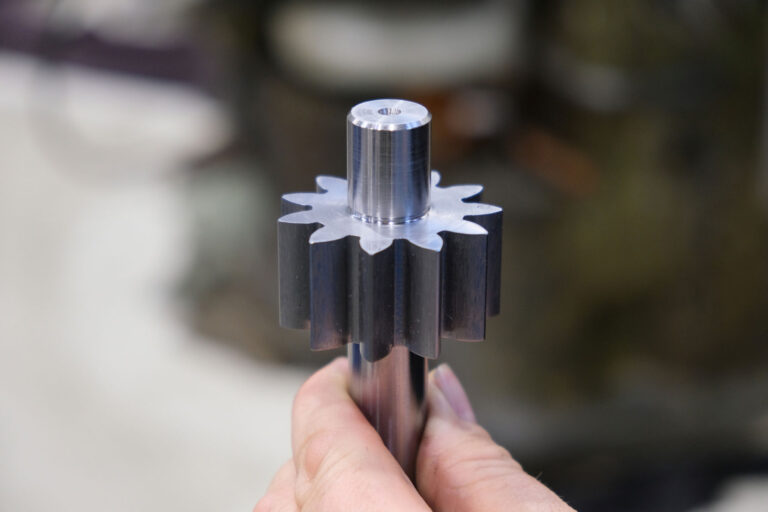

To repair the crack in the crossbeam of the turbine house, Stryvo used metal stitching—also known as “lock ‘n’ stitch.” This is a method where holes are drilled into the metal at specific intervals. Grooves are then milled out, and the parts are secured with threads. A crack is not necessarily straight, so this is a method that requires accuracy and patience. Nevertheless, it is an excellent alternative to welding when welding is not possible.

The Result

Stryvo has used this method on several occasions. It has proven to be very durable and cost-effective for the customer.

Want to learn more about metal stitching?

Read more here or contact us today.