Statkraft Nore 1: Unik og solid reparasjonsmetode

Vannkraftanlegget på Nore 1 fikk nylig utført en krevende reparasjon da en sprekk oppstod i turbinhusets tverrbjelke. Med en spesiell reparasjonsmetode som heter metallsying, tok Stryvo utfordringen med å bevare den historiske infrastrukturen uten å måtte bytte ut dyre og kompliserte deler.

Metallsying kan erstatte sveising der dette ikke er mulig, og kan dermed spare anlegg for store kostnader. Metoden er spesielt godt egnet for gamle anlegg med materialer som krever nøye behandling. Statkraft ser store fordeler ved å kombinere erfaring og nøyaktighet for å forlenge levetiden på kraftverket.

Bakgrunn

Nore 1 er et stort kraftverk, og reaksjoner i betongen utsetter mekaniske deler i kraftverket for spenninger. Det hender derfor at komponenter sprekker. Flere av komponentene er komplekse, eller innstøpte, og er derfor svært vanskelig og kostbart å skifte ut. På noen deler av anlegget er det også brukt materialer som ikke kan sveises.

Løsningen

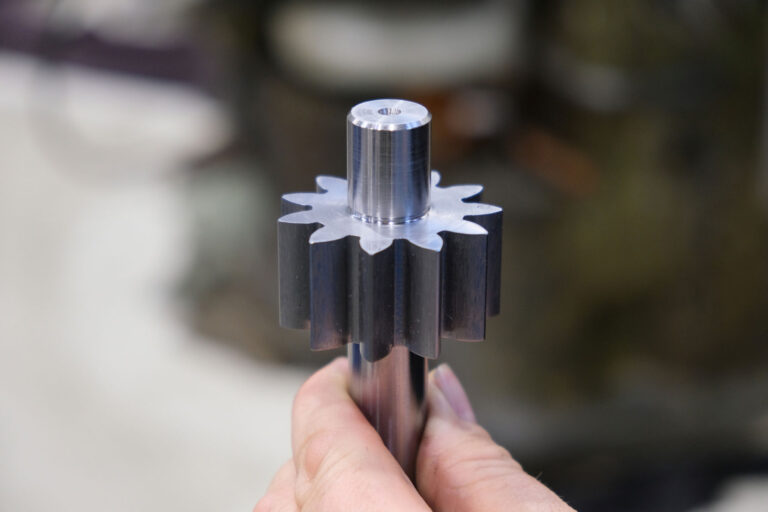

For å reparere sprekken i tverrbjelken på turbinhuset, brukte Stryvo metallsying – eller såkalt «lock ‘n’ stitch». Dette er en metode der det først bores hull i metallet med en bestemt avstand. Deretter freses det ut spor, og delene festes med gjenger. En sprekk er ikke nødvendigvis rett, derfor er dette en metode som krever nøyaktighet og tålmodighet for å gjennomføres. Likevel, er dette et veldig godt alternativ til sveising, når dette ikke er mulig.

Resultater

Metoden har blitt brukt av Stryvo ved flere anledninger. Den har vist seg svært holdbar og kostnadseffektiv for kunden.

«Vi har brukt Stryvo hos oss ved flere anledninger. Å utføre reparasjoner på et kraftverk med deler som snart er hundre år gamle, krever kunnskap og nøyaktighet. Vi ser at det er svært kostnadsbesparende å utføre vedlikehold og reparasjon i stedet for at vi må bytte til nye deler.»

Ole Gunnar Haug, vedlikeholdsleder hos Statkraft

Vil du vite mer?

Vil du vite mer om metallsying? Les mer om våre feltservicetjenester, eller ta kontakt med oss i dag.