Hafslund Kraft: Increased production by 20 GWh

When Hafslund Kraft (formerly Hafslund Eco) wanted to improve the efficiency of the hydropower plant at Osensjøen, they partnered closely with Stryvo. The project was executed with precision and high quality – significantly boosting renewable energy production.

Stryvo delivered custom equipment that ensured safe and stable operation throughout the project. With a strong focus on quality and ongoing communication, Hafslund Kraft achieved a flawless solution. The collaboration has been marked by reliability and professionalism, making Stryvo a preferred partner for hydropower projects.

Background

Hafslund Kraft is Hafslund’s hydropower business and accounts for about 13 percent of Norway’s total hydropower production. The project around Osensjøen supported national goals to optimize the utilization of already existing power plants. Hafslund Kraft has collaborated with Stryvo on several occasions, and chose Stryvo as the supplier of several crucial components for the upgrade around Osensjøen.

«We have chosen to collaborate with Stryvo on several occasions because they deliver high-quality products and ensure seamless jobs. The people at Stryvo are easy to communicate with and understand our needs. Their dedication and professionalism make them a valuable partner in our projects.»

Kurt Magne Fallingen, senior prosjektleder i Hafslund Kraft

The Solution

The project, completed in 2022, transfers water from Øvre Flisa (in Elverum and Trysil municipalities) and Østre Æra (in Åmot municipality) to Osensjøen, to increase the production of renewable energy by 20 GWh, mainly at the Osa power plant in Åmot. The project supports national objectives to optimize the use of existing regulations and power plants.

Stryvo delivered the following equipment for the various water flows:

Transfer from Østre Æra to Osa kraftverk:

- Hydraulic gate valve

- Hydraulic system

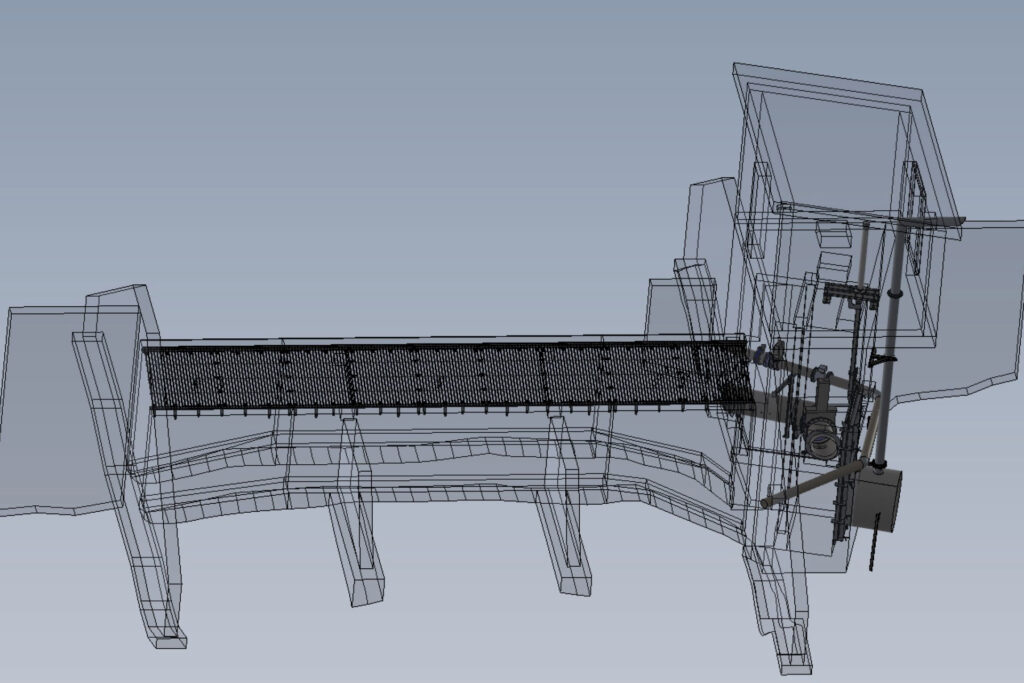

- Tyrolean weir (trash rack)

- Minimum flow pipe with electric valve

- Bottom outlet pipe with valve

- Ventilation pipe

Transfer from Øvre Flisa to Osensjøen:

- Sluice gate

- Cone in the upper valve chamber

- Pipe rupture valve

- Pipes and diffuser in the lower valve chamber

- Control valve

- Ventilation pipe

- Hydraulic system

- Minimum Flow Håsjøen

- Electriv hoists

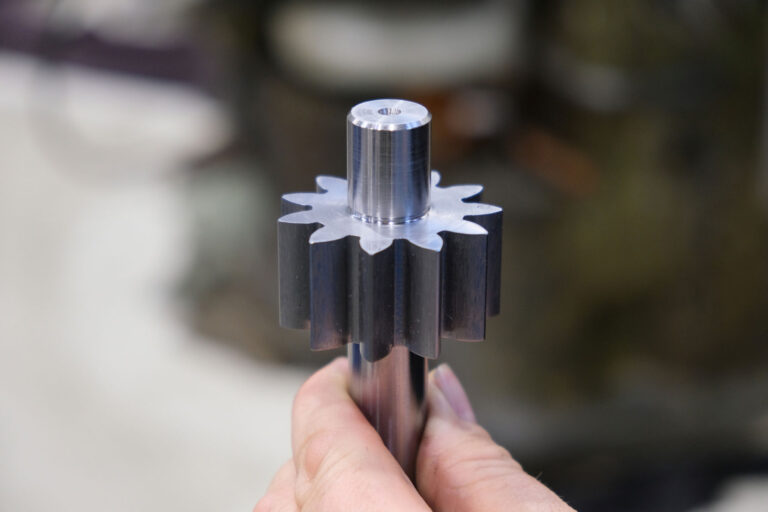

Everything was designed and produced to meet strict requirements for functionality and durability. Each phase of the project, from planning to installation, was carefully coordinated with Hafslund Kraft to ensure everything ran smoothly.

The Results

All equipment delivered by Stryvo has functioned flawlessly, contributing to stable and secure renewable energy production. Feedback from Hafslund Kraft has been positive, especially regarding Stryvo’s ability to deliver on time and maintain open and effective communication throughout the process.

Are you upgrading your power plant?

We would like to hear from you.